Air-cooled Chillers丨Recirculating Chillers丨Low Temperature Chillers

AppliCAtions:

1.petrochemical, pharmaceutical medical, bioengineering, freeze-drying, aerospace industry, semiconductor manufacturing, research and other industries.

2.Supporting: various types of reactors, vacuum chambers, experimental instruments, microchannels, etc., provide cold sources for production processes, and can also cool semiconductor equipment, dryers, evaporators, etc.

Ideal for cooling rotary evaporators.

LNEYA chillers are well-suited to a wide range of uses in the lab, like keeping your rotary evaporators cool, working with vacuum systems, plasma etching, laser etching, and jacketed reactors.

No dry ice or liquid nitrogen necessary.

Through recirculating its internal coolant, this system eliminates the need for ice, dry ice, and liquid nitrogen.

Model parameters

Cooling Capactiy Up to 8.6kW

Refrigerant R-404A/R23/R14

Power MAX 220V 5.5KW~380V 14KW

Low Temperture Chillers丨Refrigerated Circulators

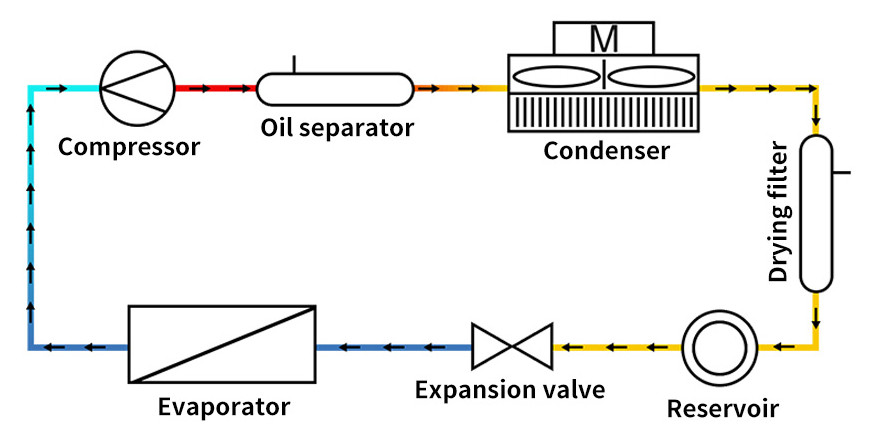

Air cooled chillers use shell and tube evaporators to exchange heat between water and refrigerant. The refrigerant system absorbs the heat in the water. After cooling the water, the heat is brought to the condenser through the compressor, and then dissipated to the outside air by the cooling fan.

Characteristics of Air-cooled Chillers:

- The air-cooled chiller does not need to be connected to a cooling tower, and is suitable for environments with poor impurities. (Impurities are easily mixed in the cold water tower, and the dust will cause the cooling water circulation circuit to be blocked, resulting in a decrease in cooling capacity).

- Air-cooled chillers are most suitable for areas with poor water quality, which can save other accessories such as cold water towers.

- The use of large-capacity condenser makes it easier and more convenient to operate.

- The floor space is reduced to a greater extent, and the installation is very convenient.

- The air-cooled chiller adopts the design of the upper air outlet.

Other Star Products

Water Chillers

Temperature Control Range: -150°C to +50°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System etc..

IC Shock Test Chiller

Temperature Control Range: -120°C to +300°C

Application: Temperature shock of chips, modules, integrated circuit boards, electronic components etc..

Vehicle Test Chillers

Temperature Control Range: -40°C to +135°C

Application: Battery life test,Fuel injector, pump test bench,Airbag Test,Component testing of power modules etc..

Cooling and Heating Systems

Temperature Control Range: -120°C to +350°C

Application:High Pressure Reactor/Double-Layer Glass Reactor/Double-Layer Reactor,Microchannel Reactor,Steaming System etc..

Eliminates Water Cooling.

This recirculating chiller system can serve as a valuable alternative to tap-water cooling in laboratory applications. Adding this unit to your setup means you can remove water cooling from most lab systems, reducing maintenance time.

Plastic industry: accurately control the mold temperature of all kinds of plastic granulation, reduce the beer molding cycle time, and ensure the stability of product quality.

Electronic industry: stabilize the molecular formula of electronic components in the production line, improve the standard rate of electronic components, apply it to the field of ultrasonic cleaning, and reasonably avoid the damage caused by the evaporation and evaporation of expensive detergent.

Electroplating field: control the electroplating temperature, improve the relative density and smoothness of plated parts, reduce the electroplating cycle time, improve productivity and improve product quality.

Mechanical Engineering: control the working pressure and oil temperature of steam pressure system software, stabilize the water temperature and steam pressure, increase the service time of oil products, improve the high efficiency of lubrication of mechanical equipment and reduce wear.

Industrial production of Engineering Construction: provide chilled water for concrete, make the molecular formula of concrete suitable for the main purpose of engineering construction, and reasonably improve the strength and ductility of concrete.

Vacuum plating: control the temperature of vacuum coating machine to ensure the high quality of plated parts.

Chemical and Pharmaceutical industry: in the medical industry, the key is to control the temperature control of hair alcohol drugs. Pharmaceutical manufacturing enterprises should flexibly use the chiller equipment, effectively strengthen technological innovation on the basis of giving full play to its advantages, improve the cost performance of the chiller, and then better serve the projects in the pharmaceutical industry.

Laser industry: used in laser marking machines, laser engraving machines, laser welding machines, laser inkjet printers, laser cutting machines and other laser processing equipment to accurately control the temperature required by the laser equipment to ensure the normal operation of the laser equipment.

Talk to us about your temperature control solution needs

Portable Chiller Working Principle

Using a single compressor, through the method of natural separation and multi- stage overlapping, the overlapping between the high boiling point components and the low boiling point components is achieved, and the purpose of preparing low temperature is achieved;

Use ethylene glycol mixed with water mixture for circulating refrigeration, strict circulating pipeline design to prevent circulating water pollution and prolong the use time of circulating water;

Fully enclosed design, no water absorption during low temperature operation, to ensure the purity of the cold heat transfer medium, prevent ice crystals, and improve the life of the heat transfer fluid;

The temperature difference between the compressor on and off can be set; the ambient temperature monitoring function prevents the system from operating ambient temperature too high.

LNEYA CHILLERS

LNEYA CHILLERS