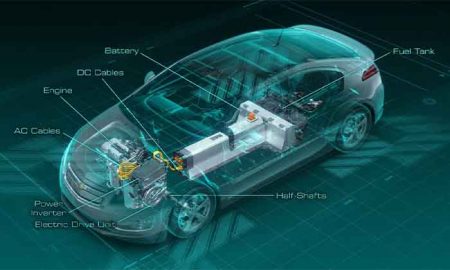

Liquid Cooling System丨Vehicles Test Chillers丨Automotive Chillers

AppliCAtions

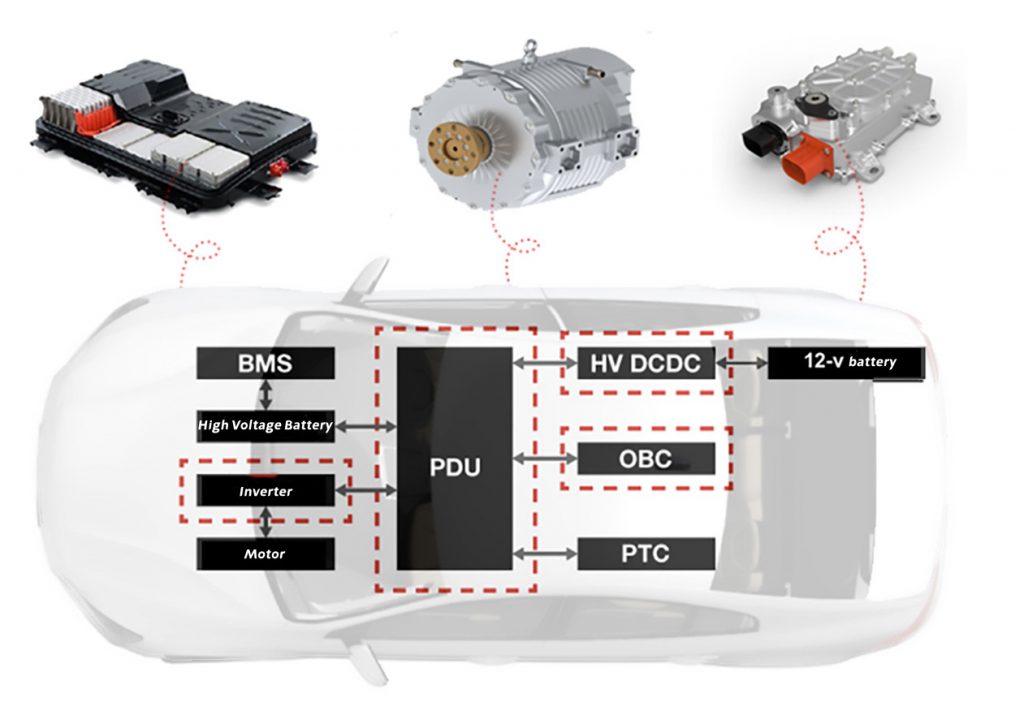

1.Applicable to the new generation of energy battery pack, which can effectively test the strong environmental adaptability of the battery pack, improve the safety and reliability of the whole vehicle, and ensure the good operation of the vehicle in a variety of complex environments;

2.Applicable to limit performance test, rapid temperature rise and fall thermal shock test and comprehensive environmental adaptability evaluation test of motor, battery pack, OBC and DC-DC products;

3.Automobile antifreeze can control the temperature and flow at the same time when it is tested at high temperature and low temperature. It can be used as a refrigeration and heating system for cold and hot shock.

Cooling Heating temperature and flow control system (for testing in the automotive industry), the refrigerant is an aqueous ethylene glycol solution. KRY series is divided into 4 temperature sections, which is convenient for various test temperature control options. Among them, the equipment in the normal temperature range of 0℃~100℃ and the low temperature section of -40℃~100℃ can control the temperature and control the flow or pressure at the same time. One KRY equipment is connected to 2 or even 3 or 6 test platforms. It can also be connected to the test box to simulate the ambient temperature when testing various parts of the car, so as to improve the quality of the car and the service life of each part.

Model Parameters

KRY series-Low Temperature -40℃~100℃

Temperature range -25°C~+100°C

Cooling Capacity Up to 38kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 11KW~45KW

Temperature range -40°C~+100°C

Cooling Capacity Up to 60kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 12KW~84KW

Temperature range -40°C ~ +100°C

Cooling Capacity Up to 38kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 30KW~158KW

1&2(Temp/Flow/Pressure)

Temperature range -40°C ~ +100°C

Cooling Capacity Up to 60*2kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 16.5KW~81KW

Temperature range -40°C ~ +100°C

Cooling Capacity Up to 60kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 23.5KW~82KW

1&3 (Temp&Flow/Pressure)

Temperature range -40°C ~ +100°C

Cooling Capacity Up to 60kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 23.5KW~82KW

KRY series-Normal Temperature -0℃~100℃

Temperature range 0°C~+100°C

Cooling Capacity Up to 60kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 4.5KW~61KW

Temperature range 0°C ~ +100°C

Cooling Capacity Up to 60*2kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 9KW~120KW

1&2(Temp/Flow/Pressure)

Temperature range 0°C ~ +100°C

Cooling Capacity Up to 60kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 17KW~65KW

1&2(Temp&Flow/Pressure)

Temperature range 0°C ~ +100°C

Cooling Capacity Up to 60kW

Temperature control accuracy ±0.5℃

Power 380V 50HZ 22KW~68KW

1&3(Temp&Flow/Pressure)

Electronic Pump Temperature Control System

KRY series &Test Chamber

Temperature range -40°C ~ +135°C

Cooling Capacity Up to 60kW

Temperature range

-45°C ~ +135°C Anti-freeze Fluid & -45°C ~ +100°C Test Chamber

Cooling Capacity Up to 7.5kW

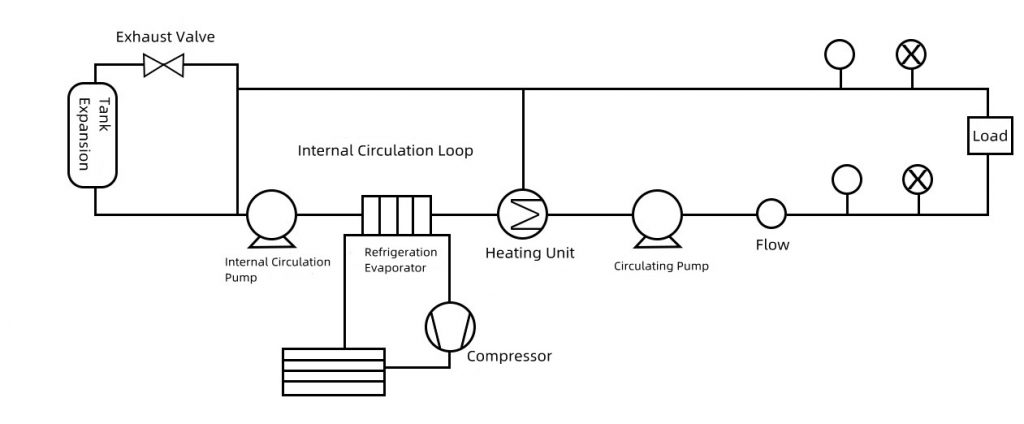

Automotive Chillers Principle Introductions

Temperature variation range is usually from -40 to 100 degrees (which can be extended to 150 degrees). While controlling the temperature, you can also choose to control the flow or pressure;

Equipped with powerful circulating pump to ensure the delivery of high viscosity liquid; Variable frequency regulation or proportional regulation valve is used to control the flow output to achieve high-precision control of 5% ~ 100% of the total range.

The temperature control equipment can be flexibly connected with other test platforms;

The liquid chiller (used in the automotive testing industry) in the above temperature range is a water-cooled chiller. Please contact us for confirmation of the specific model selection.

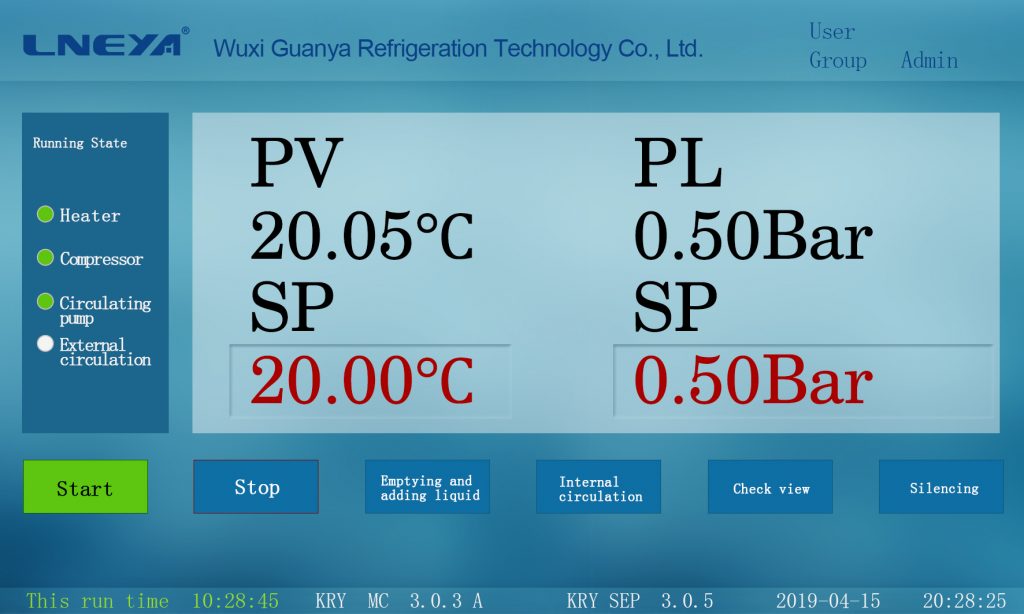

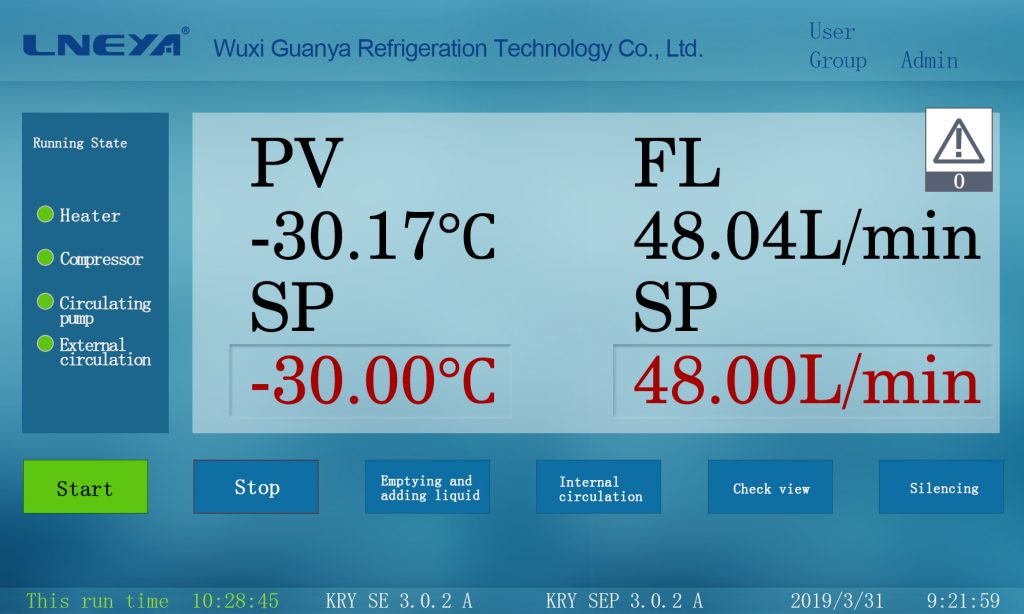

Fully enclosed system. Siemens PLC control screen and large color screen are adopted;

Clearly display the real-time control of various parameters;

Very steep temperature gradient change, visual data storage and report analysis;

Temperature control accuracy ± 0.5 ° C, flow control accuracy ± 0.2l/min;

The equipment can choose not only to control the flow, but also to control the pressure.

Video Introduction

Extensive validation in the development of wireless charging systems for electric vehicles, simulating the charging equipment and cooling circuits in the vehicle, provides temperature-controlled water glycol for short periods of time. Provides rapid temperature changes and simulates vehicle cooling circuits or environmental effects.

Battery life test

Fuel injector, pump test bench

Airbag Test

Component testing of power modules

Highly dynamic temperature control system for material and component testing enables precise regulation and rapid temperature changes. Only precise temperature management can provide reliable and reproducible results.

Application Notes

Other Star Products

Water Chillers

Temperature Control Range: -150°C to +50°C

Application: Various Reactors (Microchannels, Glass, Jacketed Reactors, etc.), Distillation or Extraction System etc..

IC Shock Test Chiller

Temperature Control Range: -120°C to +300°C

Application: Temperature shock of chips, modules, integrated circuit boards, electronic components etc..

Vehicle Test Chillers

Temperature Control Range: -40°C to +135°C

Application: Battery life test,Fuel injector, pump test bench,Airbag Test,Component testing of power modules etc..

Cooling and Heating Systems

Temperature Control Range: -120°C to +350°C

Application:High Pressure Reactor/Double-Layer Glass Reactor/Double-Layer Reactor,Microchannel Reactor,Steaming System etc..

LNEYA CHILLERS

LNEYA CHILLERS